This website uses cookies to enhance your user experience. Your interactions and personal data may be collected on our website by us and our partners in accordance with our Privacy Policy.

TRX Pro.15 carburetor settings

Note: From the factory,your carburetor has been preset to the following break-in specs. Do not readjust your carburetor settings unless you suspect that the settings have been changed or if you need to make adjustments for altitude (above 3000 ft).

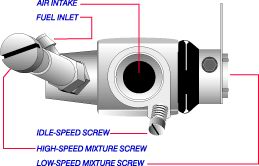

HIGH-SPEED MIXTURE SETTING

The high-speed mixture screw controls how much fuel enters the engine during

mid and high-speed operation. Turn the high-speed mixture screw clockwise, by

hand, until it stops (Do not tighten or the needle may be

damaged). Now, turn the mixture screw counter-clockwise 2 1/2 complete

turns.

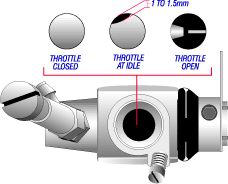

SETTING THE IDLE SPEED

The idle screw regulates the throttle opening to control the idle speed. The

throttle opening at idle should be set as shown in the drawing. The opening

should be 1 to 1 1/2 millimeters at the widest point in the opening. Make sure

that the throttle trim on the transmitter is adjusted correctly so that the

throttle arm actually rests against the idle stop screw. Do not attempt to

control your idle speed with the throttle trim control on the transmitter. The

idle speed may need to be readjusted after the engine is warm.

LOW SPEED MIXTURE SETTING

This screw meters the fuel at low speeds. The low-speed mixture screw is

located in the end of the carburetor, inside the throttle arm. This screw

controls how much fuel enters the engine at idle and low throttle. This

adjustment will smooth the idle and improve acceleration to mid-speed. Make

this adjustment with the throttle closed, after setting the idle. To get the

low speed mixture into the correct range of adjustment, turn it in or out until

the head of the screw is flush (even) with the end of the throttle arm

assembly. This will be the starting point for break in.

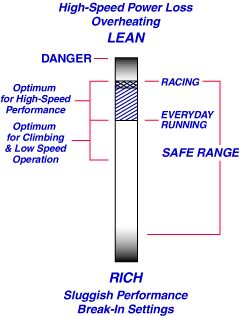

TUNING FOR POWER

TUNING FOR POWER

All final tuning adjustments must be made to the engine at its normal operating temperature after the engine has been broken-in. Click here for instructions on how to break-in the TRX Pro.15 engine. The engine's performance depends on the fuel mixture. Leaning the fuel mixture with the high-speed needle (turning clockwise) will increase engine power up to engine\'s mechanical limits. Leaning the fuel mixture beyond the safe allowable limits will result in poor performance and engine damage.

To tune the engine for maximum power. Turn the mixture screw in (clockwise) 1/16 of a turn and continue driving. Note any increase in speed and performance. Continue to lean the fuel mixture in 1/16 turn increments until :

1) There is no longer any performance increase or

2) The engine begins to cut out at high speed or

3) The engine begins to overheat

If you are using a digital temperature gauge, the Pro.15 tuned for performance runs in the range of 300º-320º F.

Overheating symptoms include:

• Steam or smoke coming from the engine surfaces

• Hesitation during acceleration (as if running out of fuel)

• Popping or clattering sound when decelerating (detonation)

• The idle speed will fluctuate

Any of the above symptoms indicate that the fuel mixture is past maximum safe lean setting. Turn the mixture screw back out (counter-clockwise) the previous 15-degrees to reach the optimum fuel mixture setting. Turn the mixture screw out another 15-degrees for non-race applications. This will extend engine component life. This setting will vary slightly with each engine depending upon fuel brand, temperature, humidity, etc.

FINE TUNING THE LOW SPEED MIXTURE

The low-speed mixture screw is located in the end of the throttle shaft. The

low speed mixture affects the idle quality and the low end engine power and

throttle response. To check your low speed mixture setting, perform this simple

test.

1) Drive the vehicle for several minutes until the engine is in its normal

operating temperature range.

2) Pull it in, stop, and listen to the idle speed. If, after a few seconds, the

idle speed begins to drop then lean the low speed mixture 1/8 of a turn

(clockwise) and retest.

3) Continue leaning the engine in small steps until the idle speed will stay

even for at least 20-30 seconds after stopping.

4) The vehicle should accelerate quickly from a standing start without bogging.

The idle should be smooth and consistent. Lean the mixture 1/8 of a turn

(clockwise) and re-test. If you experience any stalling or hesitation when

accelerating, then the low speed mixture is too lean. Richen it 1/8 of a turn

(counter clockwise) and retest.

Second test

Pinch the fuel line to the carburetor and observe how long it takes for the

engine to stall. If the engine stalls immediately, then the low speed needle is

probably set too lean. You should be able to pinch the fuel line for 1 or 2

seconds without stalling the engine. You should also hear the engine speed up

just before it stalls.

SETTING THE IDLE SPEED

Now that the engine mixture is tuned, the idle speed may be set too high. If

the model moves forward at idle, reset the idle speed by removing the air

filter and adjusting the idle speed screw on the side of the carburetor, turn

the screw clockwise to increase idle speed, counter-clockwise to reduce idle

speed. Turn the screw out (counter-clockwise) until the engine will idle

consistently (without stalling) and the model will sit still without any brake

being applied. If you are having to constantly blip the throttle to keep the

engine from stalling, then the idle speed is set too low.

Canadian Dollar (CAD)

Canadian Dollar (CAD)

Euro (EUR)

Euro (EUR)