This website uses cookies to enhance your user experience. Your interactions and personal data may be collected on our website by us and our partners in accordance with our Privacy Policy.

How To - Adjust the Slipper Clutch

Adjusting the Slipper Clutch

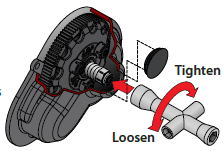

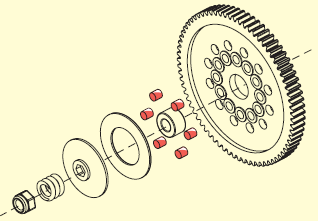

Your Traxxas model may be equipped with an adjustable slipper clutch which is built into the large spur gear. The purpose of the slipper clutch is to regulate the amount of power sent to the rear wheels to prevent tire spin. When it slips, the slipper clutch makes a high-pitch, whining noise. Remove the rubber slipper clutch plug on the transmission cover in order to adjust the slipper. Use the 4-way wrench to turn the adjusting nut clockwise to tighten and counter-clockwise to loosen. Place the model on a high traction surface, such as carpet. Adjust the slipper so that you can hear it slip for approximately two feet from a standing, full throttle start.

Rustler/Bandit/Slash/Stampede

1/16 Scale Vehicles

Nitro Rustler/Nitro Stampede/Nitro Sport/T-Maxx Classic (all vehicles with the friction peg style slipper clutch)

Slash 4X4/Stampede 4X4

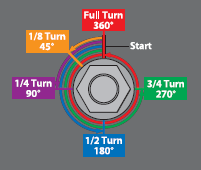

To achieve a good starting point for the slipper clutch in these models, tighten the slipper clutch adjusting nut clockwise until the slipper clutch adjusting spring fully collapses (do not over tighten), and then turn the slipper clutch nut counterclockwise one full turn.

Do not run your model with the slipper clutch adjusting spring fully compressed. The minimum recommended slipper clutch setting is 1/2 turn counter-clockwise from fully compressed.

Revo 3.3/T-Maxx 3.3 (These adjust differently than the

other vehicles)

The slipper clutch is adjusted by loosening the spring-loaded locknut on the

slipper shaft. Use the supplied 8mm open-end metric wrench. To tighten or

loosen the

slipper nut, insert the 2.0mm hex wrench into the hole in the end of the

slipper shaft. This locks the shaft for adjustments. Turn the adjustment nut

clockwise to tighten (less slippage) and counter-clockwise to loosen (more

slippage).

From the factory the slipper clutch is set for minimal slippage, just enough to

protect the drivetrain from shock loads. On slippery, low traction surfaces

such as a hard-packed, dry racetrack you may benefit from loosening the slipper

adjustment nut to allow for more clutch slippage. This will make the truck

easier and more forgiving to drive by helping to reduce the amount of wheel

spin. Loosening the slipper adjustment can also improve performance on extreme

high traction

surfaces by preventing the front end from lifting off of the ground when

accelerating. Make slipper adjustments in small 1/8 turn increments.

The maximum tight setting for the slipper is just at the point where there is

little or no tire slippage on a high traction surface such as carpet or a

prepared racetrack. The slipper should not be tightened to the point that

clutch slippage is completely eliminated. Do not overtighten the slipper nut or

you could damage the slipper bearings, pressure plates, or other

components.

Canadian Dollar (CAD)

Canadian Dollar (CAD)

Euro (EUR)

Euro (EUR)