Tuning YourTRX 2.5, 2.5R and 3.3 Engine for Best Performance

The engine's performance depends on the fuel mixture. Turn the mixtureneedles clockwise to lean the fuel mixture and counterclockwise to richen it.Leaning the fuel mixture will increase engine power up to the engine'smechanical limits. Never run the engine too lean (not enough fuel flow).Never lean the engine until it begins to cut out or stall. Leaning theengine beyond the safe allowable limits will result in poor performance andalmost certain engine damage. Indications of an overly lean mixtureinclude:

- Cutting out or sudden loss of power during acceleration.

- Overheating (temperature beyond 270° F at the glow plug)

- Little or no blue smoke coming from the exhaust.

If any of these conditions are present, stop immediately and richen the highspeed mixture 1/4 turn. The engine will probably be slightly rich at thatsetting and you can then retune for performance. Always tune for performance bystarting rich and moving leaner toward the ideal setting. Never try to tunefrom the lean side. There should always be a light stream of blue smoke comingfrom the exhaust.

Before you begin tuning, the engine should be warmed up to its normaloperating temperature and running slightly rich. All final tuning adjustmentsmust be made to the engine at its normal operating temperature. You can tellthe engine is running rich by noting any of the following:

- Sluggish acceleration with blue smoke coming from the exhaust

- The vehicle may not shift into second gear (if installed)

- There is unburned fuel spraying from the exhaust tip

- Leaning the high-speed fuel mixture increases performance

High-SpeedFuel Mixture Adjustment

Base setting for high-speed needle =four turns out from closed

With the engine warmand running at a rich setting, gradually lean the high-speed fuel mixture in1/16 turn increments. Make several high-speed passes with the vehicle aftereach adjustment to clear out the engine and note any change in performance. TRXracing engines are extremely powerful. Remember to apply the throttle graduallyto prevent wheelies or loss of control. Continue this procedure untilone of the following conditions exist:

- There is no longer any performance improvement

- The engine begins to cut out at high speed (Danger!)

- There is a sudden loss of power during acceleration (Danger!)

- The engine begins to overheat.

Symptoms of overheating include:

- Steam or smoke coming from the engine (not exhaust)

- Hesitation or stalling during acceleration

- Popping or clattering sound when decelerating (detonation)

- Fluctuating idle speed

Temperature measurement above 270° F at the glow plug If any one of theabove conditions occurs, the fuel mixture is already past the maximum safe leansetting. Richen the fuel mixture to the optimum setting by richening the highspeed needle at least 1/8 turn counterclockwise and retest. This setting willextend engine component life.

Low-SpeedFuel Mixture Adjustment

Base setting for low speed needle =flush with the grey ring around the

low-speed adjustment screw (see engine/screwdriver pic above)

The low-speed mixture is always set after the high-speed needle is correctly adjusted.Thelow-speed mixture will be set using the pinch test.

- Once the engine is warm, do several high-speed runs to confirm that the high-speed needle is set correctly.

- Bring the vehicle in and pinch closed the fuel line going into the carburetor. The engine should run for two-to-three seconds, speed up, and then die.

- If the engine runs longer than three seconds, lean the low-speed needle 1/16 turn, make several more high speed runs, and retest.

- If the engine dies immediately without speeding up, richen the low-speed needle 1/8 turn, make several more high speed runs, and retest.

When the low-speed needle is set correctly, the engine's throttle responseshould be very quick, possibly even to the point of making it difficult to keepthe vehicle from doing a wheelie when you accelerate!

Idle SpeedAdjustment

Base setting for idle stop screw =0.5mm-1.0mm gap between the slide

valve and the inside of the carburetor inlet tract (venturi).

Once the high andlow-speed mixtures have been set, reduce the idle speed to the minimum reliableidle speed. Remember, this adjustment should be made while the engine isrunning at normal operating temperature.

- Turn the throttle trim on the transmitter so that the brakes are applied. This ensures that the throttle slide is resting against the idle adjustment screw.

- If necessary, remove the air filter to gain access to the idle adjustment screw.

- Turn the screw counterclockwise to reduce the idle speed, or clockwise to increase it. The idle speed should be set as low as possible while still maintaining reliable running characteristics.

- Reset the throttle trim on the transmitter.

Note: If the idle speed is settoo high it could prevent the T-Maxx from shifting between forward and reverse.If you experience this, simply reduce the idle speed.

Fine-Tuningthe Carburetor

After fine-tuning your TRX engine at the end of the break-in procedure, nomajor adjustments to the fuel mixture are usually necessary. Make note of thetemperature, humidity, and barometric pressure at the time you finished finetuning your carburetor. Current weather conditions can be found online fromnational websites, local TV news websites, and Television. This informationwill be considered your baseline setting.

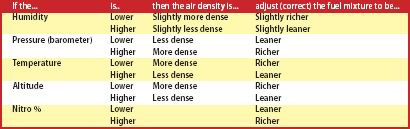

You may need to adjust your carburetor needles to compensate for changes intemperature and barometric pressure (air density) from day to day. Generally,you'll need to richen the fuel mixture when the weather is colder than yourbaseline temperature and the air density is higher. Lean the fuel mixture whenweather is warmer than your baseline temperature and the air density is lower.The chart below provides general guidelines on how weather conditions affectair density when they move higher or lower than your baseline setting.

Canadian Dollar (CAD)

Canadian Dollar (CAD)

Euro (EUR)

Euro (EUR)